We make forged wheels since 2018.

Our company has existed since 2009. In the beginning we were selling discs of famous world brands, but at one point we realized that our accumulated knowledge and capabilities allow us to become an independent manufacturer.

Now we produce forged wheels not only for private clients and tuning studios, but we are also suppliers for racing series, which have special requirements to the quality of the product. We are not limited to the domestic market, our rims can be seen on cars in Europe, America and the Arab Emirates!

We devote a great deal of attention to engineering and experimentation.

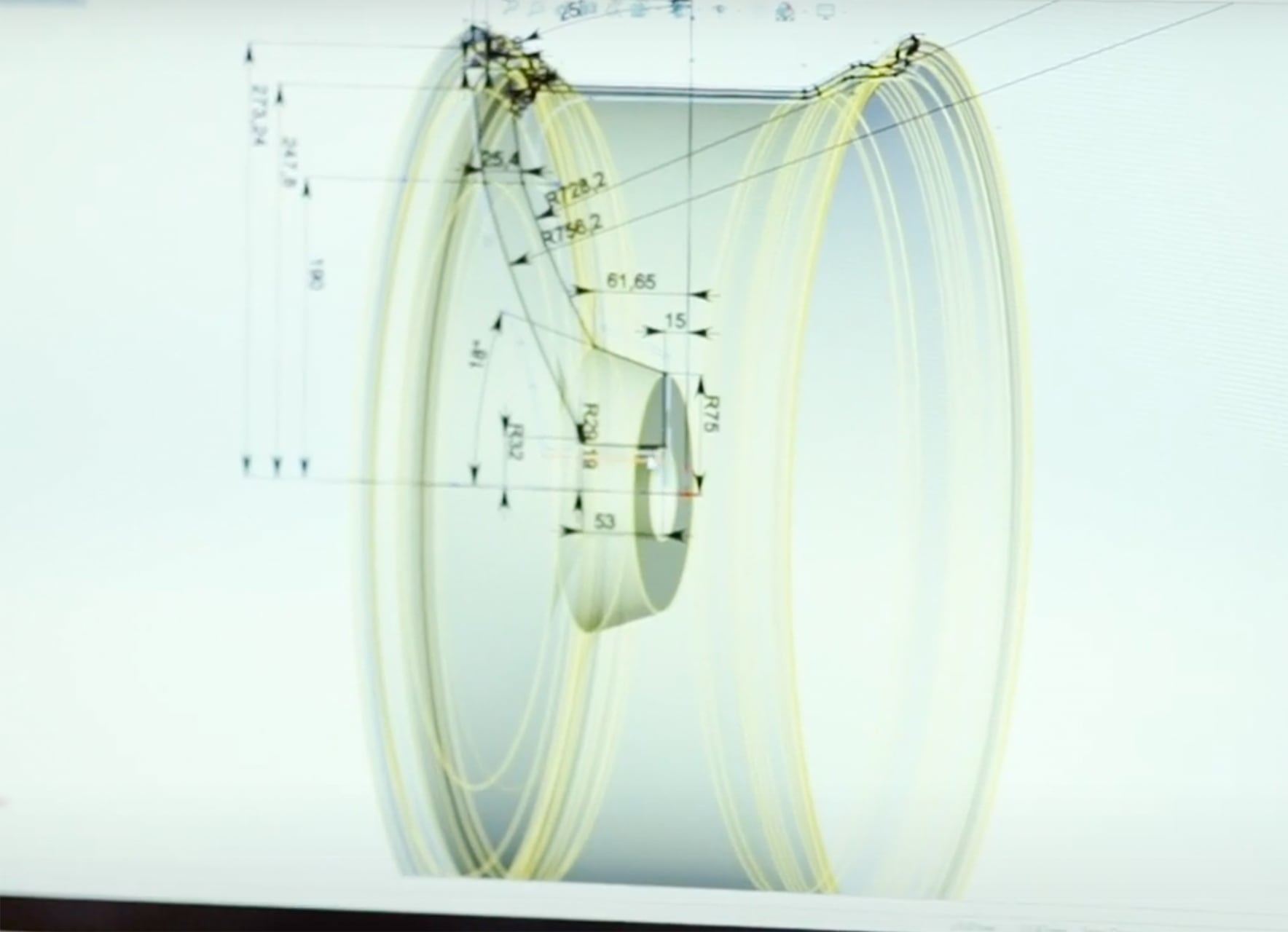

Each wheel goes through a thorough design and analysis process. This makes it possible to get a product that covers all the needs of our customers’ cars, taking into account their wishes and production capabilities.

All wheels models undergo a finite element analysis (FEA) based on the specifications of the specific vehicle and in accordance with GOST 33544-2015, SAE J2530, JWL and VIA standards. Only after verification by our engineers, the model is sent for programming for production on the CNC machines.

Experience that we implement all the time.

At Power Wheels, we have extensive experience in the design, engineering, and manufacturing of wheels for a wide variety of vehicles. We factor in the type of vehicle, the use-case of the vehicle, the driving style of the owner, and what the owner’s intentions are with the vehicle.

We then calculate and develop and engineering model that will ensure our wheels will perform perfectly and stand the test of time. Don’t be fooled by the beauty of our wheels, behind this beauty is hundreds or sometimes thousands of manhours from our team to ensure the wheel has both beauty and brains.

We use billets of alloy 6061-T6

All over the world, forged wheels are mainly made of 6061-T6 aluminum, thanks to its excellent balance of weight and strength characteristics. There are no secrets here for a long time now, but what is important is how the billet is made, and there are a lot of technical nuances.

To get the best raw materials, we cooperate with Russian manufacturers on an ongoing basis, ordering from them blanks according to their drawings with the desired characteristics

We use only high-precision CNC machines.

Using CNC milling and turning machines, we can achieve extremely tight tolerances, minimizing any rim runout and surface defects. According to Russian GOST the standard for radial and axial run-out is 0.5 mm, but we consider 0.4 mm to be the limit, which allows for low run-out and no vibration of the wheels at high speeds.

In order not to overheat the die while milling (which leads to a decrease in the strength characteristics of the metal), the machine processes one wheel in an average of 12 hours. Depending on complexity, some designs can take up to 35 hours of production per wheel.

Finishes

The finishing stage is one of the most important for the visual evaluation of the product, and here we have transferred all the quality of foreign techniques and materials to our discs.

The quality of brushed depends on the experience of the specialist who makes it. This process cannot be automated, as every line and curve of the disc must be machined manually. We can confidently say that the brushed that comes out from under the hands of our craftsmen is one of the best in the world!

.

Quality control

In order to achieve high quality, we pay a lot of attention to the material from which the future wheel will be made. All over the world, forged wheels are made mainly from aluminum of 6061-T6 grade, as this alloy is used in aerospace industry due to its excellent balance of weight and strength characteristics. There are no secrets here for a long time, but the way the stamping is made is important, and there are a lot of technical nuances.

In order to select the best raw materials, we began to work closely with factories, as a result, some stamps are made according to our drawings. Constant communication with die makers allows us to improve the quality of future stampings. And for us, to satisfy the quality of future wheels.